Concrete pipe seals, also known as concrete pipe gaskets or concrete pipe joint seals, are crucial components used to provide watertight and secure connections between concrete pipes in various underground and above-ground infrastructure systems. These seals are designed to prevent the leakage of fluids, including water, sewage, and other liquids, from concrete pipe joints. They are commonly used in stormwater management, sewage systems, drainage systems, and culverts. Here’s more information about concrete pipe seals:

1. Types of Concrete Pipe Seals:

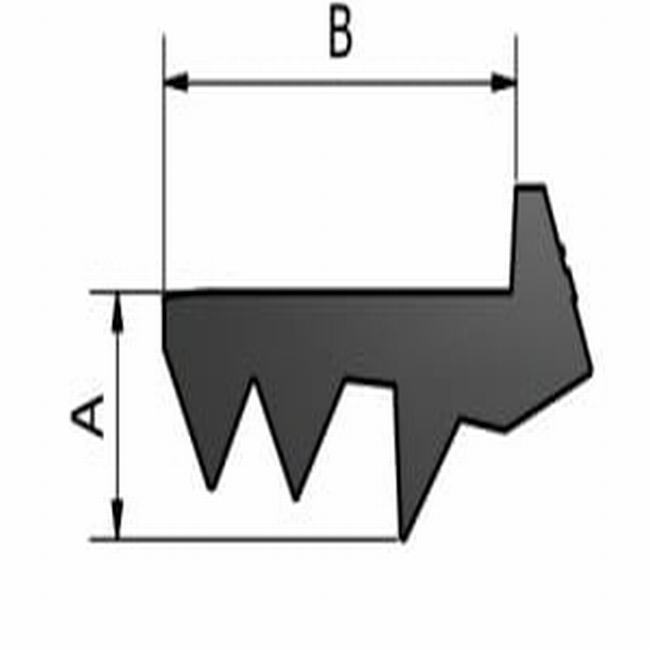

- Rubber Ring Gaskets: Rubber ring gaskets are the most common type of concrete pipe seals. They are made from materials like EPDM (Ethylene Propylene Diene Monomer), neoprene, or natural rubber. These gaskets are positioned within the bell or socket end of the concrete pipe and create a watertight seal when the pipes are joined.

- Mastic or Sealant: Some concrete pipe joints use mastic or sealant compounds in addition to or in place of rubber gaskets. These compounds are applied to the joint surface to create a seal when the pipes are connected.

2. Functions:

- Watertight Seal: The primary function of concrete pipe seals is to create a watertight and airtight seal between the pipe joints. This prevents the infiltration of groundwater into sewage systems and the exfiltration of sewage into the surrounding soil.

- Load Transfer: In addition to sealing, concrete pipe seals often provide load transfer capabilities, helping to distribute the weight and external loads applied to the pipes.

3. Features and Benefits:

- Resistance to Chemicals: Concrete pipe seals are designed to resist the chemicals commonly found in sewage and drainage systems, ensuring long-term durability and reliability.

- Ease of Installation: Rubber ring gaskets are relatively easy to install, allowing for efficient and cost-effective pipe joint assembly.

- Longevity: High-quality concrete pipe seals can withstand environmental conditions, including temperature variations, UV exposure, and moisture, ensuring a long service life.

- Variety of Sizes: These seals are available in various sizes to accommodate different concrete pipe diameters and applications.

- Compliance: Many concrete pipe seals are manufactured to meet industry standards and regulatory requirements for sealing performance.

4. Installation:

- Installing concrete pipe seals typically involves placing the gasket within the bell or socket end of the concrete pipe before joining the pipes together. The seal is compressed as the pipes are pushed or pulled together, creating a secure and watertight connection.

5. Applications:

- Concrete pipe seals are used in a wide range of applications, including:

- Sewage systems and wastewater treatment plants.

- Stormwater management systems.

- Culverts for water conveyance.

- Drainage systems for roads, highways, and airports.

- Irrigation and agricultural drainage systems.

Properly installed concrete pipe seals are essential for maintaining the integrity of underground and above-ground infrastructure systems. They play a critical role in preventing leaks and ensuring the efficient flow of fluids, making them integral components of various civil engineering and construction projects.