Concrete pipe seals, also known as pipe gaskets or pipe joint seals, play a crucial role in the construction and maintenance of underground and aboveground infrastructure systems, particularly in the field of wastewater management, stormwater drainage, and various utility pipelines. These seals are designed to provide a reliable and durable barrier against water infiltration, soil intrusion, and other potential contaminants in pipelines constructed from concrete or reinforced concrete segments.

Here is a detailed description of concrete pipe seals, covering their types, functions, materials, and key features:

- Types of Concrete Pipe Seals:

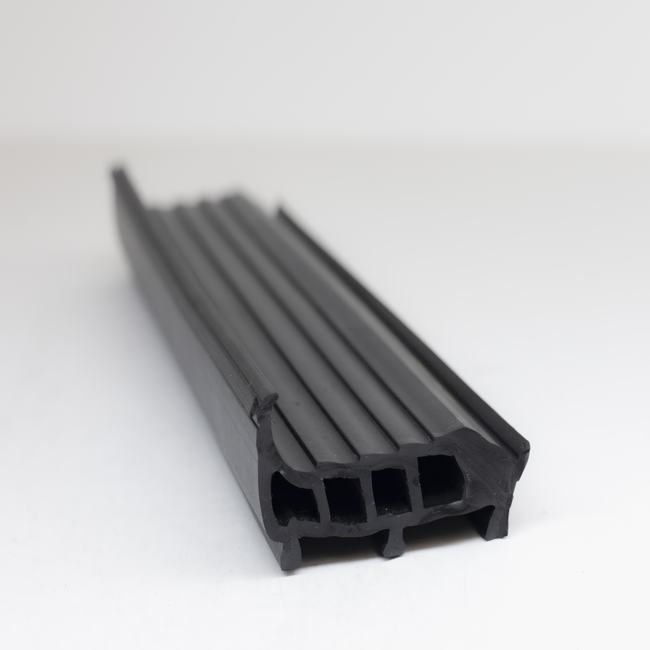

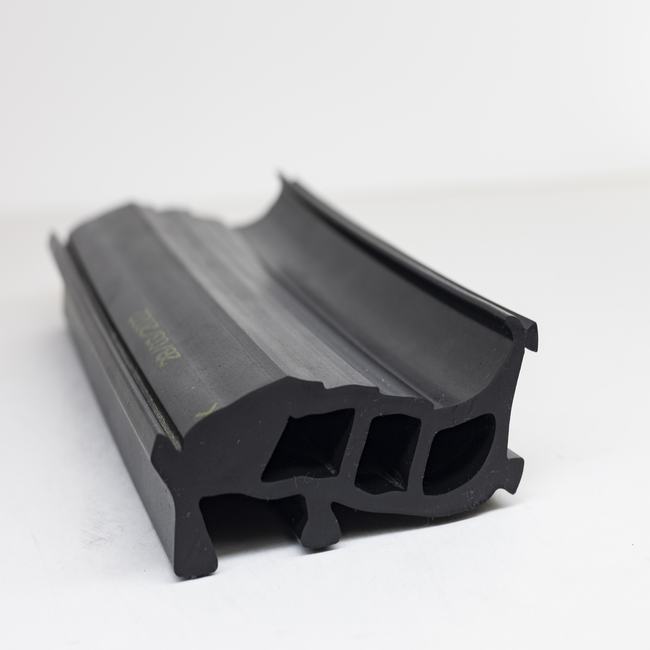

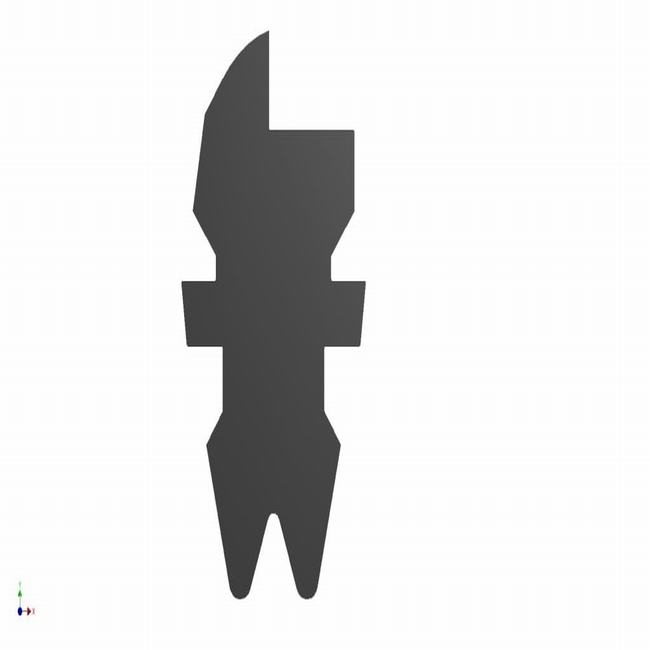

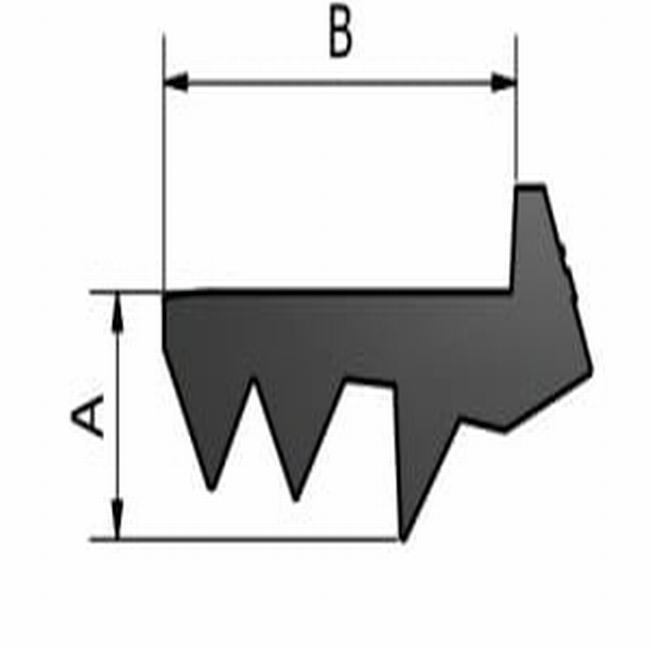

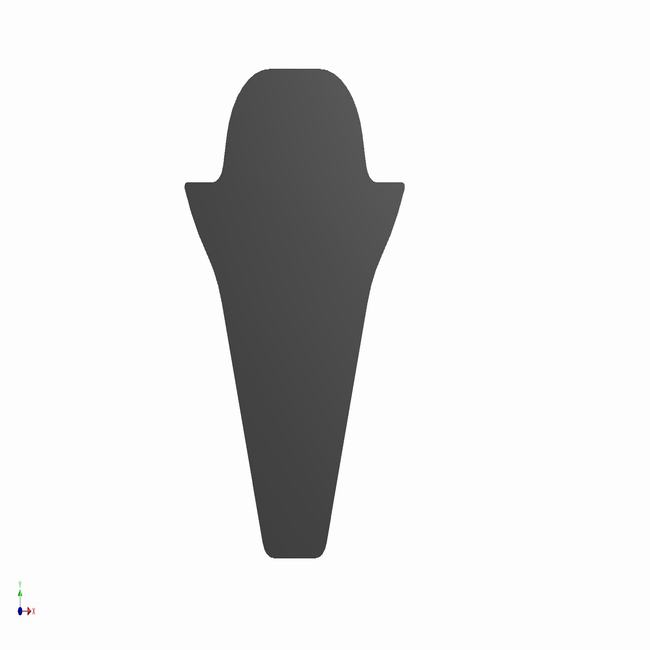

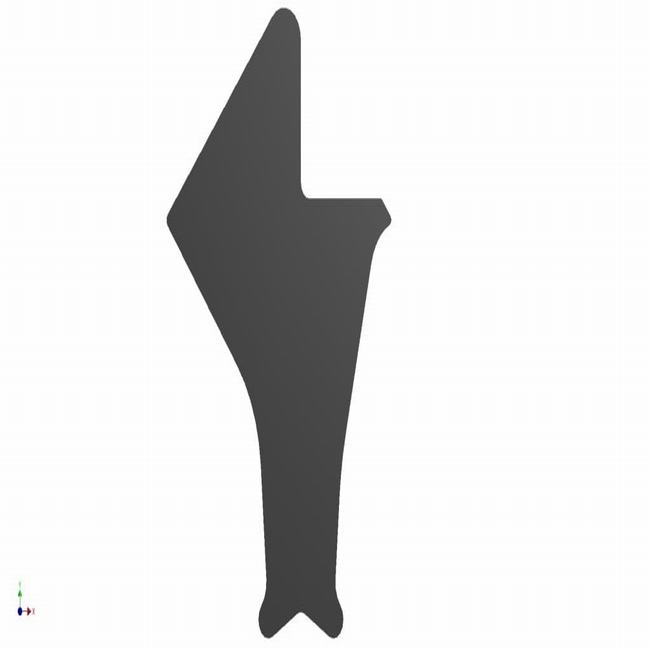

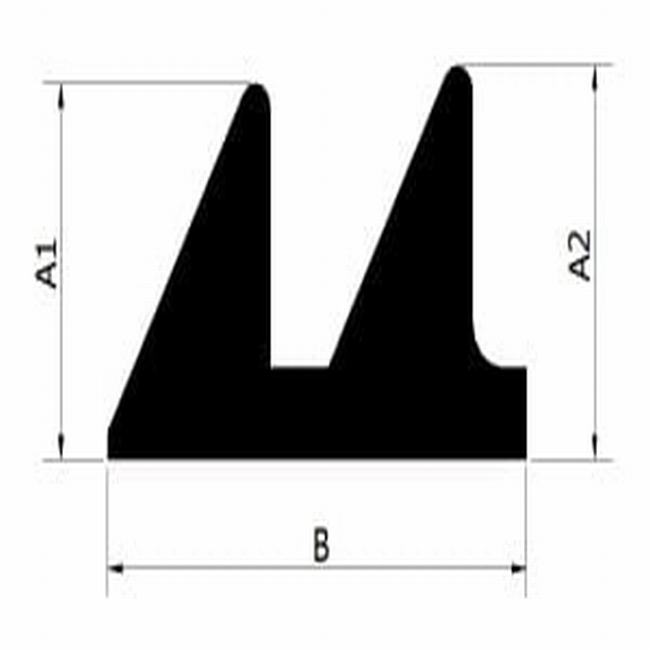

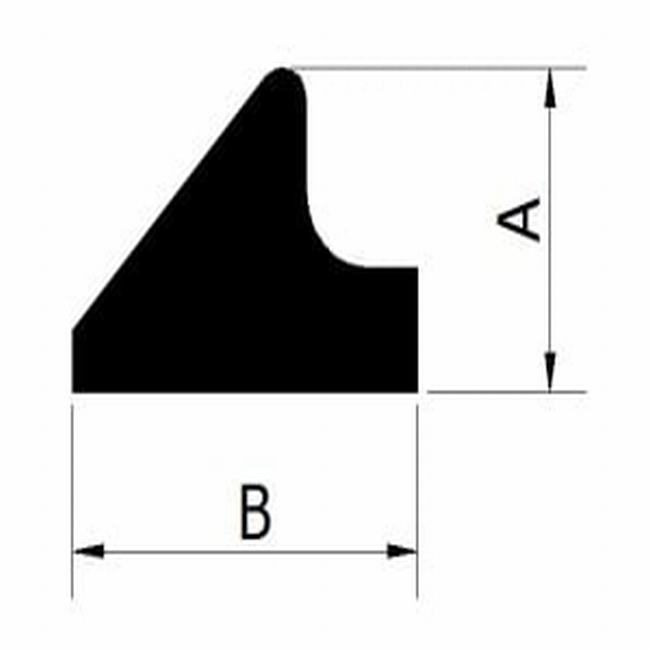

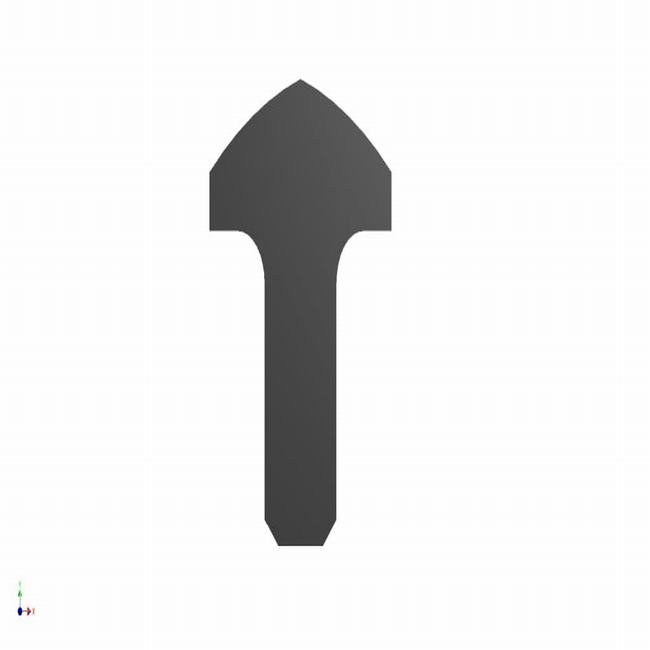

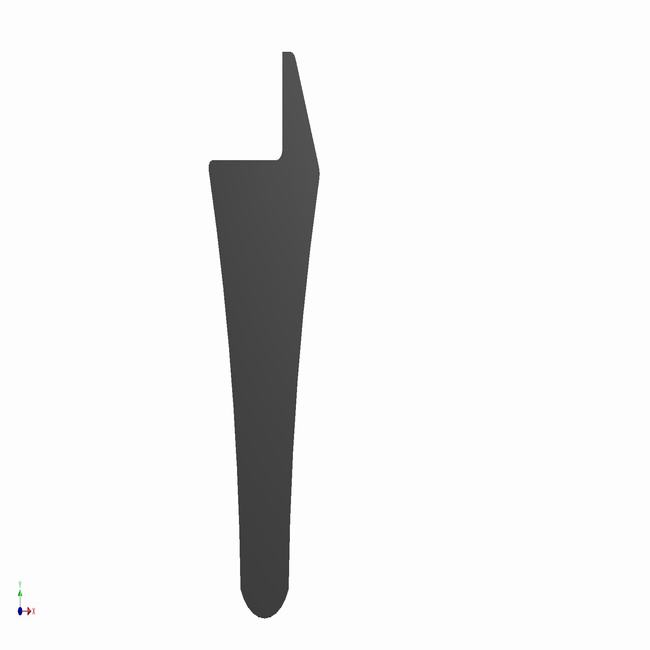

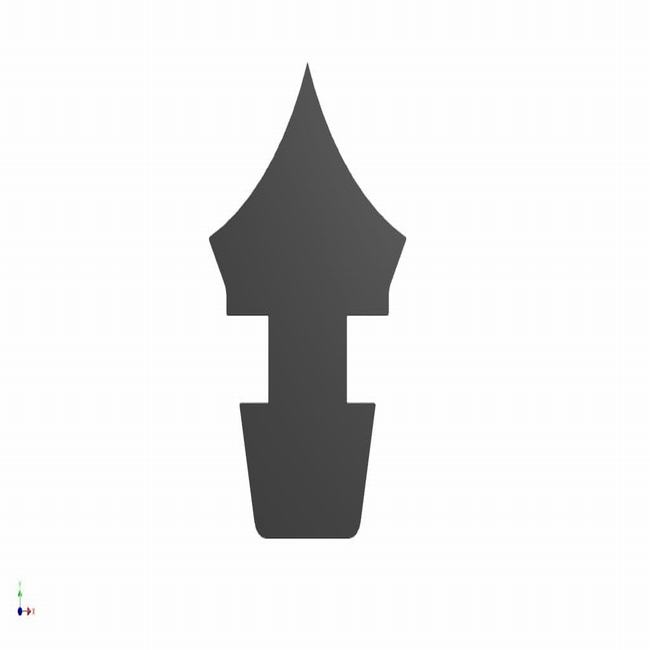

- Rubber Gaskets: The most common type of concrete pipe seal is made of rubber or elastomeric materials. These gaskets come in various shapes and sizes to fit different pipe profiles, including circular, elliptical, and rectangular pipes.

- Lubricated Seals: Some concrete pipe seals are pre-lubricated with a special compound to ease the installation process and ensure a watertight seal.

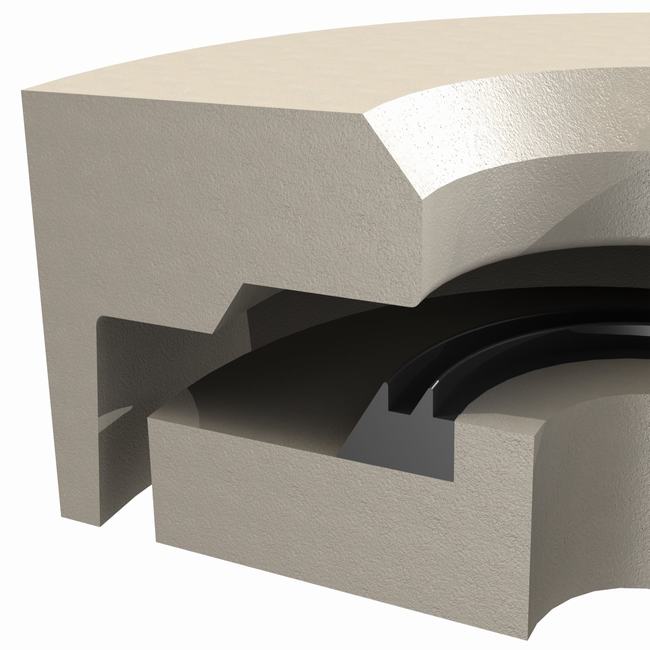

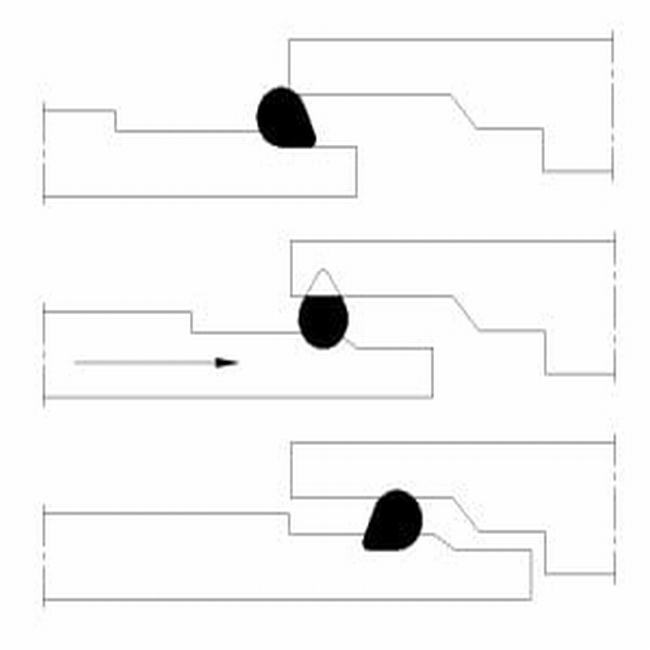

- Compression Seals: These seals are designed to create a tight seal when the concrete pipes are compressed together during installation.

- Functions:

- Water Tightness: The primary function of concrete pipe seals is to prevent water from leaking into or out of the pipe system. This is crucial for maintaining the integrity of sewage systems and preventing environmental contamination.

- Soil and Debris Exclusion: These seals also serve as a barrier against soil infiltration, preventing the surrounding earth from entering the pipe and causing blockages or structural damage.

- Chemical Resistance: Depending on the application, concrete pipe seals may be engineered to resist various chemicals present in wastewater or industrial effluents.

- Structural Integrity: In addition to their sealing properties, some concrete pipe seals contribute to the structural integrity of the pipeline by enhancing its resistance to external loads and ground settlement.

- Materials:

- EPDM (Ethylene Propylene Diene Monomer): EPDM rubber is a common material for concrete pipe seals due to its excellent resistance to weathering, UV exposure, and chemical degradation.

- Nitrile Rubber: Nitrile rubber gaskets are often used in applications where oil resistance is required.

- Neoprene: Neoprene rubber offers good resistance to oils, ozone, and weathering and is suitable for various pipe sealing applications.

- Key Features:

- Durability: Concrete pipe seals are designed to withstand harsh environmental conditions and maintain their sealing integrity over extended periods.

- Ease of Installation: Lubricated seals and compression seals are engineered for easy installation, reducing labor time and costs.

- Customization: Manufacturers can produce concrete pipe seals in various shapes and sizes to fit specific pipe dimensions and requirements.

- Compliance: High-quality seals meet industry standards and regulatory requirements for water tightness and structural performance.

In conclusion, concrete pipe seals are essential components in the construction and maintenance of pipelines, ensuring the integrity of underground and aboveground infrastructure systems. These seals come in various types, materials, and designs to meet the diverse needs of different applications while providing long-lasting, reliable performance in harsh environmental conditions.